CNC Machining Services – Global Precision Manufacturing Solutions

CNC Machining: High-Precision Custom Parts for Industries Worldwide

CNC machining (Computer Numerical Control machining) is one of the most advanced, reliable, and widely used manufacturing processes for producing high-precision custom parts across industries worldwide. From aerospace and automotive to medical, electronics, energy, and industrial manufacturing, CNC machining plays a critical role in modern production.

At cncmachining.site, we provide professional online CNC machining services designed for global customers who demand accuracy, consistency, speed, and reliability. Our services support rapid prototyping, low-volume manufacturing, and full-scale production, delivering precision-engineered components that meet international standards.

Unlike generic manufacturing platforms, cncmachining.site focuses on engineering-driven CNC machining, combining advanced equipment, skilled expertise, and strict quality control to ensure repeatable results for every project.

What Is CNC Machining?

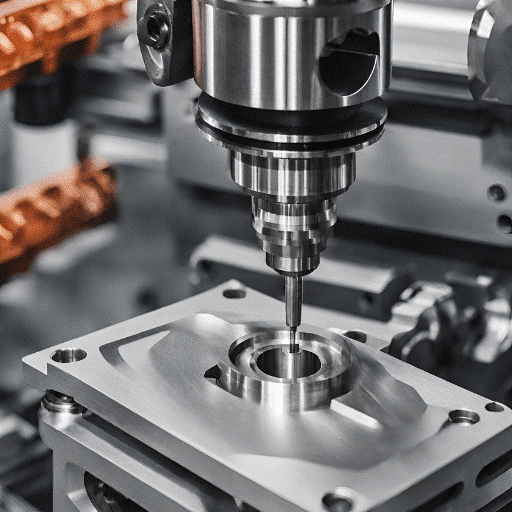

CNC machining is a subtractive manufacturing process in which material is removed from a solid block (workpiece) using computer-controlled machine tools. These tools include CNC mills, lathes, routers, and multi-axis machining centers that follow pre-programmed instructions (G-code) to achieve extremely precise movements.

Because CNC machines operate digitally, they can consistently reproduce complex designs with tight tolerances that are difficult or impossible to achieve using manual machining.

Key Characteristics of CNC Machining

- Computer-controlled automation

- High dimensional accuracy

- Repeatability across batches

- Ability to machine complex geometries

- Scalability from prototype to production

CNC machining is widely trusted because it balances precision, efficiency, and material strength, making it suitable for functional and production-grade parts.

How CNC Machining Works (Step-by-Step)

1. CAD Design

The process begins with a 2D or 3D CAD model, created using professional design software. This model defines every dimension, tolerance, and feature of the part.

2. CAM Programming

The CAD model is converted into CAM (Computer-Aided Manufacturing) instructions. CAM software generates G-code, which controls:

- Tool paths

- Spindle speed

- Feed rates

- Cutting depth

- Tool changes

3. CNC Machining Process

The CNC machine reads the G-code and automatically performs milling, turning, drilling, tapping, or contouring operations. Material is removed with high precision until the final part is achieved.

4. Inspection and Quality Control

Finished parts are inspected using precision measuring tools to ensure dimensional accuracy, surface finish, and compliance with specifications.

Types of CNC Machining Services We Offer

CNC Milling Services

CNC milling uses rotating cutting tools to remove material from a stationary workpiece.

Capabilities include:

- 3-axis, 4-axis, and 5-axis CNC milling

- Complex geometries

- Tight tolerances

- Flat, contoured, and angled surfaces

Applications: aerospace components, automotive brackets, industrial housings, tooling plates.

CNC Turning Services

CNC turning uses a rotating workpiece and stationary cutting tools, ideal for cylindrical or rotational parts.

Capabilities include:

- High-precision CNC lathe machining

- Excellent concentricity

- Smooth surface finishes

Applications: shafts, bushings, pins, connectors, sleeves.

Multi-Axis CNC Machining

Multi-axis machining enables complex parts to be produced in fewer setups.

Benefits:

- Higher accuracy

- Reduced setup time

- Better surface finish

- Complex geometries in a single operation

Materials for CNC Machining

CNC machining supports a wide range of engineering and industrial materials, making it extremely versatile.

Metals

- Aluminum

- Stainless Steel

- Carbon Steel

- Brass

- Copper

- Titanium (project-dependent)

Plastics

- ABS

- Nylon

- Delrin (POM)

- Polycarbonate

- Acrylic (PMMA)

Other Materials

- Engineering plastics

- Composites

- Specialty industrial materials

Material selection depends on strength, weight, corrosion resistance, temperature performance, and application requirements.

Advantages of CNC Machining

CNC machining offers several advantages over other manufacturing methods:

Precision and Accuracy

- Tolerances as tight as ±0.01 mm

- Consistent dimensional accuracy

Repeatability

- Identical parts across batches

- Ideal for production runs

Design Flexibility

- Complex geometries

- Internal features and tight radii

Production Scalability

- Prototypes to mass production

- No redesign required

Surface Finish

- Excellent surface quality

- Minimal post-processing

CNC Machining vs Additive Manufacturing (3D Printing)

Both CNC machining and 3D printing are used in modern manufacturing, but they serve different purposes.

| Feature | CNC Machining | 3D Printing |

|---|---|---|

| Manufacturing Type | Subtractive | Additive |

| Accuracy | Very High | Moderate |

| Surface Finish | Excellent | Average |

| Material Strength | High | Medium |

| Production Use | Prototypes + Production | Mostly Prototypes |

CNC machining is preferred for functional, load-bearing, and high-performance parts.

Industries We Serve Worldwide

CNC machining supports nearly every modern industry.

Aerospace

- Lightweight, high-strength components

- Tight tolerances

- Safety-critical parts

Automotive

- Engine components

- Brackets and housings

- Fixtures and tooling

Medical

- Surgical instruments

- Precision medical components

- High cleanliness requirements

Electronics

- Enclosures

- Heat sinks

- Precision connectors

Industrial Manufacturing

- Machinery parts

- Jigs and fixtures

- Custom tooling

Energy, Robotics & Automation

- Structural components

- Precision mechanical parts

Startups & R&D

- Rapid prototyping

- Product validation

- Design iteration

Online CNC Machining Services – Global Access, Local Precision

Modern manufacturing demands speed, transparency, and reliability. cncmachining.site delivers CNC machining through a streamlined online workflow:

- Upload your CAD design

- Receive a detailed quote

- Production begins

- Parts are inspected and shipped globally

Our global CNC machining approach ensures consistent quality, competitive pricing, and dependable lead times for customers worldwide.

Why Choose cncmachining.site?

There are many CNC machining platforms available today, including large global networks such as Hubs, Protolabs, Xometry, JLCNC, PCBWay, and others. While these platforms serve the market at scale, cncmachining.site focuses on a different value:

What Sets Us Apart

- Engineering-focused machining

- Direct quality control

- Custom project support

- Tight tolerance capability

- Global service mindset

We position ourselves as a precision-driven CNC machining partner, not just a transactional marketplace.

Quality Control and Inspection

Quality is critical in CNC machining. Our inspection process includes:

- Dimensional verification

- Surface finish checks

- Visual inspection

- Process validation

This ensures every part meets specifications before shipment.

CNC Machining for Prototypes and Production

CNC machining is ideal for:

- Functional prototypes

- Pre-production validation

- Low-volume manufacturing

- High-volume production

The same machining process can be scaled without design changes, making CNC machining a reliable long-term manufacturing solution.

Frequently Asked Questions (CNC Machining)

What does CNC mean in machining?

CNC stands for Computer Numerical Control, referring to automated machine control using programmed instructions.

Is CNC machining hard to learn?

Basic CNC operation is relatively easy to learn, while advanced programming and multi-axis machining require experience.

Is CNC machining in high demand?

Yes. CNC machining is in high demand globally due to its role in modern manufacturing.

Does CNC machining require math?

Basic geometry, measurements, and trigonometry are commonly used in CNC machining.

Will AI replace CNC machining?

AI will enhance CNC machining but will not replace skilled machinists and engineers.

How long do CNC machines last?

With proper maintenance, CNC machines can last 15–25 years or more.

Custom CNC Machining for Global Manufacturers

If you are searching for:

- CNC machining services

- Online CNC machining

- Custom CNC machining manufacturer

- CNC milling and turning services

- Precision CNC parts supplier

cncmachining.site is your global CNC machining partner.

Get a CNC Machining Quote Today

Ready to manufacture high-quality CNC parts with confidence?

📩 Upload your design

⚙️ Precision CNC machining

🚚 Worldwide delivery

cncmachining.site — Global CNC Machining Built for Accuracy, Reliability, and Scale .

Advanced CNC Machining Techniques Used in Precision Manufacturing

Modern CNC machining goes far beyond basic milling and turning. Advanced CNC machining techniques allow manufacturers to produce complex, high-tolerance parts in fewer setups, with higher accuracy and superior surface finishes. The video above demonstrates real-world CNC machining strategies used in high-precision production environments.

At cncmachining.site, we apply similar advanced CNC machining techniques to deliver reliable, production-ready components for customers worldwide.

Helical Milling for Deep Precision Features

One of the most effective CNC machining techniques shown in the video is helical interpolation. Instead of plunging straight into the material, the cutting tool enters at a controlled angle, gradually spiraling down to the required depth.

Benefits of helical milling:

- Reduced tool wear

- Improved chip evacuation

- Better surface finish

- Lower cutting forces

This technique is ideal for deep bores, internal profiles, and high-precision cavities commonly used in aerospace and industrial CNC machining applications.

Multi-Axis CNC Machining for Complex Geometry

The video highlights advanced 5-axis CNC machining, where the milling spindle and rotary axes move simultaneously. This allows the machine to create complex shapes such as octagons, angled slots, and internal features that would be difficult or impossible with traditional 3-axis machining.

Advantages of multi-axis CNC machining:

- Fewer setups

- Higher accuracy

- Improved part consistency

- Reduced production time

At cncmachining.site, multi-axis CNC machining enables us to manufacture complex components in a single setup, ensuring tight tolerances and repeatable quality.

High-Efficiency Roughing and Material Removal

Efficient roughing strategies are essential in CNC machining to remove large amounts of material while maintaining part rigidity. The video demonstrates aggressive but controlled roughing passes using indexable and long-reach cutting tools.

Key roughing considerations include:

- Tool rigidity

- Harmonic vibration control

- Optimized feed rates and step-over

- Maintaining part stability

Proper roughing reduces machining time while protecting tool life and part accuracy.

Precision Finishing for Tight Tolerances

After roughing, finishing operations refine the part to its final dimensions. The video shows finishing passes using smaller diameter tools, ball-nose end mills, and form tools to achieve precise features and smooth surfaces.

Precision finishing is critical for:

- Tight dimensional tolerances

- Functional mating surfaces

- Aesthetic quality

- Reduced post-processing

Our CNC machining processes are designed to deliver excellent surface finishes with minimal secondary operations.

Specialized Tooling for Advanced CNC Machining

The machining process shown uses a variety of advanced tools, including:

- Necked-back end mills for rigidity

- Ball-nose cutters for fillets and angled walls

- Shrink-fit tool holders for deep reach machining

- Chamfer and deburring tools for edge finishing

Using the right tooling allows CNC machines to produce complex parts efficiently and consistently.

Deburring and Edge Finishing Inside the CNC Machine

A key advantage of advanced CNC machining is completing deburring and edge finishing during the machining cycle. As shown in the video, specialized chamfer and lollipop tools eliminate sharp edges without manual labor.

This approach:

- Improves part consistency

- Reduces manual finishing time

- Enhances product quality

- Lowers overall production cost

Why Advanced CNC Machining Matters

Advanced CNC machining techniques allow manufacturers to:

- Produce complex parts in fewer operations

- Achieve tighter tolerances

- Improve repeatability

- Scale from prototype to production

Industries such as aerospace, automotive, medical devices, robotics, and industrial equipment depend on these techniques for high-performance components.

CNC Machining Expertise at cncmachining.site

At cncmachining.site, we apply proven CNC machining techniques like those shown in the video to deliver precision custom parts for global customers. Our capabilities include:

- CNC milling (3-axis to 5-axis)

- CNC turning

- Complex internal features

- Tight-tolerance machining

- Production-ready quality

Whether you need rapid prototyping or full-scale production, our CNC machining processes are built for accuracy, reliability, and scalability.

🌍 Top 12 Global CNC Machining Service Providers & Industry Leaders

When searching for CNC machining services, engineers, manufacturers, and product teams often compare multiple providers to evaluate capabilities, precision, scalability, and reliability. Below is a curated list of leading CNC machining service providers worldwide, including established global platforms and specialized precision manufacturers.

This comparison helps customers understand the CNC machining landscape while highlighting why cncmachining.site stands out as a trusted global partner.

1. cncmachining.site – Global Precision CNC Machining Partner

cncmachining.site provides professional online CNC machining services for customers worldwide. The platform focuses on custom precision CNC parts, supporting CNC milling, CNC turning, and multi-axis machining for prototypes and production.

Key strengths:

- Precision-driven CNC machining

- Custom parts manufacturing

- Online design upload and quoting

- Global delivery

- Engineering support and quality control

2. Protolabs

Protolabs is a well-known global manufacturing service offering automated CNC machining with instant pricing. Their services support rapid prototyping and low-volume to production-scale manufacturing using CNC milling, turning, and finishing processes.

3. Xometry

Xometry operates an on-demand manufacturing marketplace that connects customers with a large network of CNC machining suppliers. Their platform supports CNC milling, CNC turning, and multi-axis machining, primarily serving prototypes and production components through digital quoting.

4. Hubs (formerly 3D Hubs)

Hubs is a global online manufacturing platform offering CNC machining services through a distributed supplier network. The service includes CNC milling, turning, surface finishing, and design-for-manufacturing (DFM) feedback.

5. Fictiv

Fictiv provides a digital manufacturing platform that connects customers to CNC machining partners worldwide. Their services focus on CNC milling and turning with an emphasis on quality management, transparency, and streamlined production workflows.

6. RapidDirect

RapidDirect specializes in competitively priced CNC machining services, offering CNC milling and turning for prototypes and production parts. The company is known for fast turnaround times and integrated manufacturing solutions.

7. PartsBadger

PartsBadger is an online CNC machining service that allows customers to order custom CNC machined parts through a simplified quoting and ordering system. It primarily serves engineers, designers, and manufacturers requiring fast access to machined components.

8. Star Rapid

Star Rapid offers CNC machining alongside rapid tooling, injection molding, and metal additive manufacturing. Their CNC services support multiple industries, including aerospace, automotive, and consumer products.

9. Mekalite

Mekalite provides precision CNC machining services from prototyping to mass production. The company focuses on high-quality CNC parts for industrial, automotive, electronics, and mechanical applications.

10. Renjie Precision

Renjie Precision is a CNC machining manufacturer specializing in CNC milling and turning of complex precision parts. The company serves international customers across automotive, medical, aerospace, and consumer industries.

11. KERN Microtechnik GmbH

KERN Microtechnik is a German precision engineering company known for high-precision micro-machining and advanced CNC manufacturing solutions. Their services target applications requiring extremely tight tolerances.

12. Metro Steel USA

Metro Steel USA provides CNC machining and metal fabrication services, including milling and turning for industrial, aerospace, and automotive applications, with a focus on U.S. manufacturing standards and quality.

Why Many Manufacturers Choose cncmachining.site

While large CNC machining platforms such as Protolabs, Xometry, and Hubs serve the market at scale, cncmachining.site focuses on precision, customization, and engineering-driven manufacturing.

By combining:

- Advanced CNC machining capabilities

- Strict quality control

- Custom project support

- Global accessibility

cncmachining.site delivers CNC machining solutions tailored to real-world manufacturing needs—from prototypes to production.

Choosing the Right CNC Machining Partner

When selecting a CNC machining service provider, consider:

- Precision and tolerance capability

- Supported materials and processes

- Quality assurance methods

- Scalability from prototype to production

- Communication and engineering support

A reliable CNC machining partner ensures consistent quality, predictable lead times, and manufacturing confidence.